Toward a circular apparel industry where nothing is wasted

Across the apparel industry, a product is discarded after being worn only seven to 10 times on average. Global fashion production has also more than doubled since 2000, with increased impacts on natural resources.

Aside from knowing that we must be responsible stewards of the resources we use, the business case for cultivating greater circularity in our value chain is clear: the raw materials used to produce LS&Co. products represent 8% of our carbon footprint. Sourcing more sustainable materials and implementing a circular approach that keeps materials in use as long as possible reduces our footprint.

We are committed to playing a central role in taking the apparel industry to a circular future — one where materials are used and reused safely, where ecosystems are protected and regenerated, and where people have good work and livelihoods. This means making products with their next use in mind. It means we no longer talk about end of life, but about end of use. And it means evolving each part of the apparel supply chain toward a circular economy — starting with our own.

For 168 years, we have focused on long-wearing clothing, and when it comes to product sustainability, we have accomplished a lot. From innovations like Water<Less® to F.L.X. to cottonized hemp, we’ve initiated — and implemented — great ideas that reduce the impacts of our products and help advance sustainable apparel. We have also begun offering consumers more options to keep their denim in use longer, such as through Levi’s® Tailor Shops, and to buy vintage Levi’s® products through SecondHand, instead of always buying brand new.

The Business Case for Circular Apparel

Circular business models deliver value to LS&Co. stakeholders by creating new revenue streams, driving strategic growth and fostering innovation. In fact, circular business models specifically involving rental and recommerce were determined in a recent study by Fashion for Good and Accenture to be financially viable for fashion retailers.

Circular products also mitigate risks throughout the supply chain by using more sustainable fibers and fabrics made with safer chemicals, less water, less energy and less waste. They support healthier workplaces for the people in our supply chain, from farm to factory to retail store. They reduce our company’s exposure to environmental risks and reduce our share of garment waste in landfills. They meet growing consumer demand for more sustainable and circular apparel options. And they retain value for our customers by extending product life and usability.

The Business Case for Circular Apparel

Circular business models deliver value to LS&Co. stakeholders by creating new revenue streams, driving strategic growth and fostering innovation. In fact, circular business models specifically involving rental and recommerce were determined in a recent study by Fashion for Good and Accenture to be financially viable for fashion retailers.

Circular products also mitigate risks throughout the supply chain by using more sustainable fibers and fabrics made with safer chemicals, less water, less energy and less waste. They support healthier workplaces for the people in our supply chain, from farm to factory to retail store. They reduce our company’s exposure to environmental risks and reduce our share of garment waste in landfills. They meet growing consumer demand for more sustainable and circular apparel options. And they retain value for our customers by extending product life and usability.

Circularity Challenges

Of course, moving to a circular business model is not without its challenges, even outside a global pandemic. In addition to changing mindsets, beliefs and perceptions, there are practical hurdles as well. For instance, some promising new fibers that support circularity cost more, have longer lead times or are less durable. Some plant- or mineral-based “natural” dyes can produce too much color variability. Safer chemicals sometimes pose scaling challenges due to lack of resources for industrial use or because safer alternatives are not as easy for suppliers to use as the chemical they are designed to replace. And while many suppliers are eager to partner with us on more sustainable innovations, a supply chain spread across many countries makes it more difficult to apply new approaches everywhere in a short period of time.

We are tackling many of these challenges through our own innovation hub, the Eureka Innovation Lab; through the sustainable design practice that is our WellThread® line; and through collaboration with other brands and leading organizations working to deliver more sustainable, circular and less resource-intensive apparel. For example, we recently joined Fashion for Good to accelerate and scale cutting-edge R&D and start-up technology that can be applied to the apparel value chain. We plan to leverage Fashion for Good’s expertise and network to create pilots that address the most pressing sustainability issues in our value chain.

We will begin our focus on collaborative projects to address the challenges of plastics, sorting technologies for recycling garments, fiber transparency and traceability, and the potential to shift from wet to dry fabric and garment finishing processes. And we continue to work closely with our suppliers, many of whom have been with us for more than a decade, to partner on solutions to challenges around water use, emissions and worker health and well-being.

The Power of Collaboration

Transforming an industry is hard work that takes years, not months. We don’t have all the answers, but we know we can go further, faster and at greater scale by teaming up with others, whether other retail brands, manufacturers who share our vision for a circular economy, or nonprofits.

By participating with organizations like Fashion for Good, which funds and scales sustainable innovation, and circular apparel initiatives like the Ellen MacArthur Foundation’s Jeans Redesign project, we are collaborating with others to realign the industry and create economies of scale. We are also a sponsor of the 27-country Healthy & Sustainable Living Study underway by GlobeScan, which looks at consumer opinions about circularity, among other topics, to help us in our continued efforts to better understand consumer needs and move from a sell-what-you-make approach to a make-what-you-sell approach.

We are also working with industry groups, such as the Policy Hub and the European Branded Clothing Alliance to inform development of European Union policy that supports the transition to a more circular, less resource-intensive apparel sector.

Our Circular Strategy

By its very nature, circular fashion is intended to create a closed loop. But it has to start somewhere. For us, circularity starts with originality, bold ambitions, pioneering principles and fundamental philosophies that guide our ideation and design from the earliest stages. As we move forward, our merchandising, design, product development and marketing teams have embraced a circular mindset in keeping with the Ellen MacArthur Foundation’s Make Fashion Circular vision to make sure our products are:

- Used more – kept at the highest value at all times

- Made to be made again – designed so they can be reused, remade, recycled and safely composted

- Made from safe and recycled or renewable inputs – to protect the health of people and ecosystems

By integrating circularity at the design stage, we can develop products that last, can be repaired if necessary and can be reused or recycled — building a more sustainable and circular system. When designed with consideration for not just their next wear, but also their next life, our products can help transition the apparel industry from the take-make-waste model to one capable of rebuilding and restoring resources.

We are developing a strategy to be circular-ready in 2025. This would mark the first milestone in our holistic approach to circularity, in which we stand up each of the three pillars of the Make Fashion Circular framework and identify changes in production and innovation so that LS&Co. is “ready” for a circular economy. Our approach will make the most of existing and planned cross-functional sustainability innovations and programs in sustainable materials and production, circular business models, product design, recommerce, consumer engagement and other areas. Concurrently, we will strive to foster positive social impacts in the supply chain, working to ensure a just transition to a circular economy. Governance procedures and key performance indicators will help us track progress and accountability.

There is much more to do, but we took meaningful action in 2020, launching important circular product innovations like our WellThread® jeans with Circulose® fiber, growing sustainable fiber initiatives like cottonized hemp, exploring rental options for selected products, and joining Fashion for Good for ongoing projects.* We also launched Buy Better, Wear Longer, our consumer-focused invitation to join the circular fashion journey along with us by making conscious purchasing decisions and managing consumption.

*Circulose® is a registered trademark of Re:NewCell AB.

Made to Be Used More

We are leveraging the durability, quality and timeless style of our products to help consumers use their garments more and longer. We are scaling our SecondHand recommerce platform; continuing to grow our Levi’s® Authorized Vintage line; expanding our in-store Tailor Shops, where people can repair, repurpose and customize their “pre-loved” jeans or Trucker jackets; piloting rental programs; and partnering with diverse organizations to upcycle our products.

As we push ourselves to create more sustainable products at scale, we will also encourage consumers to keep them as long as possible before passing them on to friends or relatives, returning them to a Levi’s® store, updating them for a new look, upcycling them into new items, or recycling them when the time is right and the infrastructure is in place.

Durability and Reuse: Standing the Test of Time

Across all LS&Co. brands, we use innovations and practices that help our products stand the test of time, and everything we make is rigorously tested for durability. We are committed to keeping our clothing in use as long as possible in support of a circular economy. Levi’s® Tailor Shops can repair or redesign clothing to literally last a lifetime. In the U.S., we also introduced SecondHand in 2020 to extend the life of our products even further and offer customers access to popular vintage styles.

We have also made vintage products available through clothing rental programs. In 2020, we teamed up with Ganni on a for-rent-only capsule collection of upcycled denim made from vintage Levi’s® 501® jeans. Known as Love Letter, this is the first rental-only collection from the Levi’s® brand and will extend across the UK and United States. So far, pieces include a button-down shirt, jeans and a shirtdress, available to rent for up to three weeks. Items are shipped with reusable material for returning them.

Selling vintage Levi’s® products through Sellpy and sales platforms like Re/Done is another way to give consumers even more access to vintage clothing and support the circular economy. We are piloting additional peer-to-peer programs in Europe.

Tailor Shop – Repair, Reimagine, Recycle

One of the unique aspects of denim — and Levi’s® pieces in particular — is that they’re a blank canvas for the wearer to make their own. The Levi’s® Tailor Shop concept was designed with that very desire in mind.

Grounded in the Levi’s® brand’s heritage of craftsmanship and commitment to authentic self-expression, Tailor Shops allow fans to get beloved pieces repaired or updated with their own personal stamp. Tailor Shops reflect the emotional connection of the wearer to their cherished garment — and to the brand — while unlocking creativity through customized pieces. Some Levi’s® stores have a Tailor Shop, and our tailors have also taken their talents to festivals to reach customers outside the retail world, sometimes traveling by bicycle or trailer to get where they are needed.

Over the years, expert tailors have taken well-worn or torn pieces and reworked them, added embroidery, paint or patches to customize an item, turned shorts into wallets or patches, even sewn non-Levi’s® items like a baby blanket onto a Trucker jacket. Tailor Shop content is also available on the Levi’s® blog for DIYers who want to learn from Levi’s® master tailors how to embellish, repair, or upcycle their denim.

In 2020, we also offered virtual denim upcycling workshops in Taiwan and Hong Kong, in collaboration with designer Jesse Lee.

Tailor Shop – Repair, Reimagine, Recycle

One of the unique aspects of denim — and Levi’s® pieces in particular — is that they’re a blank canvas for the wearer to make their own. The Levi’s® Tailor Shop concept was designed with that very desire in mind.

Grounded in the Levi’s® brand’s heritage of craftsmanship and commitment to authentic self-expression, Tailor Shops allow fans to get beloved pieces repaired or updated with their own personal stamp. Tailor Shops reflect the emotional connection of the wearer to their cherished garment — and to the brand — while unlocking creativity through customized pieces. Some Levi’s® stores have a Tailor Shop, and our tailors have also taken their talents to festivals to reach customers outside the retail world, sometimes traveling by bicycle or trailer to get where they are needed.

Over the years, expert tailors have taken well-worn or torn pieces and reworked them, added embroidery, paint or patches to customize an item, turned shorts into wallets or patches, even sewn non-Levi’s® items like a baby blanket onto a Trucker jacket. Tailor Shop content is also available on the Levi’s® blog for DIYers who want to learn from Levi’s® master tailors how to embellish, repair, or upcycle their denim.

In 2020, we also offered virtual denim upcycling workshops in Taiwan and Hong Kong, in collaboration with designer Jesse Lee.

Levi’s® by Levi’s®

A new product solution — Levi’s® by Levi’s® — is made from entirely repaired, reimagined and recycled Levi’s® products and is currently only available at Levi’s® Haus, London. Made exclusively of Levi’s® faulty and returned items, as well as donations from employees and consumers, the products enable shoppers to shop more sustainably. Levi’s® Haus, London also offers the Levi’s® Vintage Clothing line and a Tailor Shop.

The Levi’s® by Levi’s® program has also collaborated with designers to create one-of-a-kind pieces featuring indigo dip dyeing and leftover furnishing fabrics.

Levi’s® by Levi’s®

A new product solution — Levi’s® by Levi’s® — is made from entirely repaired, reimagined and recycled Levi’s® products and is currently only available at Levi’s® Haus, London. Made exclusively of Levi’s® faulty and returned items, as well as donations from employees and consumers, the products enable shoppers to shop more sustainably. Levi’s® Haus, London also offers the Levi’s® Vintage Clothing line and a Tailor Shop.

The Levi’s® by Levi’s® program has also collaborated with designers to create one-of-a-kind pieces featuring indigo dip dyeing and leftover furnishing fabrics.

Levi’s® Haus, London

Opened in 2020, Levi’s® Haus, London reflects our sustainable approach to the retail experience, centering around longevity and circularity. The first of its kind for the Levi’s® brand, this unique space serves as a new blueprint for an in-store consumer experience and is dedicated to making Levi’s® products last even longer. Whether customers need a simple patch repair or want to create something entirely new from their pre-loved jeans, Levi’s® Haus, London exists to help customers extend the life of their denim.

Levi’s® Haus, London

Opened in 2020, Levi’s® Haus, London reflects our sustainable approach to the retail experience, centering around longevity and circularity. The first of its kind for the Levi’s® brand, this unique space serves as a new blueprint for an in-store consumer experience and is dedicated to making Levi’s® products last even longer. Whether customers need a simple patch repair or want to create something entirely new from their pre-loved jeans, Levi’s® Haus, London exists to help customers extend the life of their denim.

Durable Glamour

A 2021 collaboration with Prada Group’s Miu Miu features pre-owned 501® jeans and Trucker jackets from the 1980s and 1990s, revamped with playful embellishment and color. By customizing these extremely durable, vintage garments, Miu Miu has elevated them for the luxury market. Other collaborations with Nordstrom and Gallerie Lafayette extend availability of our vintage products to an even broader range of consumers.

Durable Glamour

A 2021 collaboration with Prada Group’s Miu Miu features pre-owned 501® jeans and Trucker jackets from the 1980s and 1990s, revamped with playful embellishment and color. By customizing these extremely durable, vintage garments, Miu Miu has elevated them for the luxury market. Other collaborations with Nordstrom and Gallerie Lafayette extend availability of our vintage products to an even broader range of consumers.

Authorized Vintage

Vintage Levi’s® jeans and jackets are some of the most coveted items for people shopping secondhand. Levi’s® Authorized Vintage is our proprietary resale capsule in which we source and re-sell authentic pieces, many of which are decades old.

Authorized Vintage

Vintage Levi’s® jeans and jackets are some of the most coveted items for people shopping secondhand. Levi’s® Authorized Vintage is our proprietary resale capsule in which we source and re-sell authentic pieces, many of which are decades old.

Levi’s® SecondHand

Buying used garments instead of new saves water, reduces greenhouse gas emissions and cuts waste.

Levi’s® SecondHand platform aims to help consumers do just that. Launched in 2020 as a pilot, Levi’s® SecondHand makes some of our most-loved vintage items available to consumers and invites them to join us in a more sustainable future. The platform gives jeans, jackets and shorts a second, third or fourth life, while providing consumers with the confidence they’re getting something that’s still in great shape and that consumes a fraction of the natural resources a new garment would require.

Levi’s® SecondHand is both a buy-back and resale platform. It gives Levi’s® fans the ability to purchase second-hand Levi’s® jeans and jackets, and turn in worn jeans and jackets in-store for a gift card toward a future purchase. The program encourages people to not throw away used denim and helps them see that second-hand garments can help preserve the natural resources that would be needed to make a new item. Trove, a recommerce company, cleans the collected garments and processes inventory. Cleaning, repurposing and repairing jeans uses a minimal amount of energy and water, and no dyes. Buying a used pair of Levi’s® jeans saves approximately 80% of the carbon emissions compared to buying a new pair, according to ThredUp.

So far, the SecondHand program is in the U.S. only as we learn more about what consumers want when it comes to recommerce. We hope to extend it globally for even greater positive environmental impacts. Amid growing consumer interest, the recommerce market is projected to double over the next five years, and we want to make our vintage products available to as many customers as possible.

In addition, if jeans are too worn or damaged to sell again, consumers can still drop them off at a Levi’s® store for recycling. We also give them a gift card toward a future purchase. Our partner Blue Jeans Go Green then converts that used denim into insulation for buildings, a greener alternative to standard insulation. We also take back unwanted denim in the U.K. and Germany, along with partner ICO, and offer smaller take-back programs in the Middle East and Australia.

Used Clothing Collected in 2020

- ~10,000 items of denim (Americas)

- 4,355 kg of denim (Europe)

Vintage Items on SecondHand

- SecondHand units sold in October-November 2020: 1,132

- Units posted for sale on the SecondHand site in 2020: 4,799*

*Number of units sent to Trove, including consumer trade-ins, vintage products from resellers and Levi.com returns. Remaining 3,667 units were available on the SecondHand site into FY21.

Made to Be Made Again

We continue advancing design and material innovations to make clothes that can be made again, using safe, recycled and renewable inputs that contribute to a more circular product cycle. This includes:

- Ensuring our suppliers adhere to the Screened Chemistry protocols LS&Co. has developed over the past decade to support the health and safety of supply chain workers, promote healthier water systems and help us work toward the goal of safely compostable materials at the end of our products’ useful lives.

- Using responsibly-sourced fibers like organic cotton and cellulosics certified by Canopy to not have come from Ancient and Endangered Forests. We also believe that more sustainable fibers make a better quality garment.

- Revolutionizing the use of water-saving hemp to make it soft and comfortable like cotton.

- Partnering with innovators like Re:NewCell on state-of-the-art fibers made from post-consumer recycled jeans and other responsible components.

- Expanding the application of our WellThread® design methodology — a reinvention of the total concept-to-consumer value chain that prioritizes sustainability and circularity at every stage of the product life cycle.

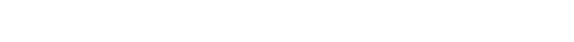

Eureka Innovation Lab

Innovation is complicated and expensive, but we’re committed to relearning how to make our products and scaling our innovations. Some of this begins at the Eureka Innovation Lab, where a diverse team of creative thinkers, scientists, technology experts and others continue the pioneering legacy started by Mr. Levi Strauss himself in the late 1800s. The lab conducts research at the component level, investigating fiber, fabric, fit, finish and functionality to develop the best holistic solutions. And because the lab includes a small factory, ideas can be made and tested in-house to see if they are viable and scalable.

Early on, the lab tackled the challenge of Screened Chemistry, playing a role in moving the industry to consider chemical hazards instead of risks. This is notable because hazards are inherent dangers in any process, while risks measure the level of exposure to those dangers. By tackling hazards, we can address the cause of the risk, rather than just addressing its effects.

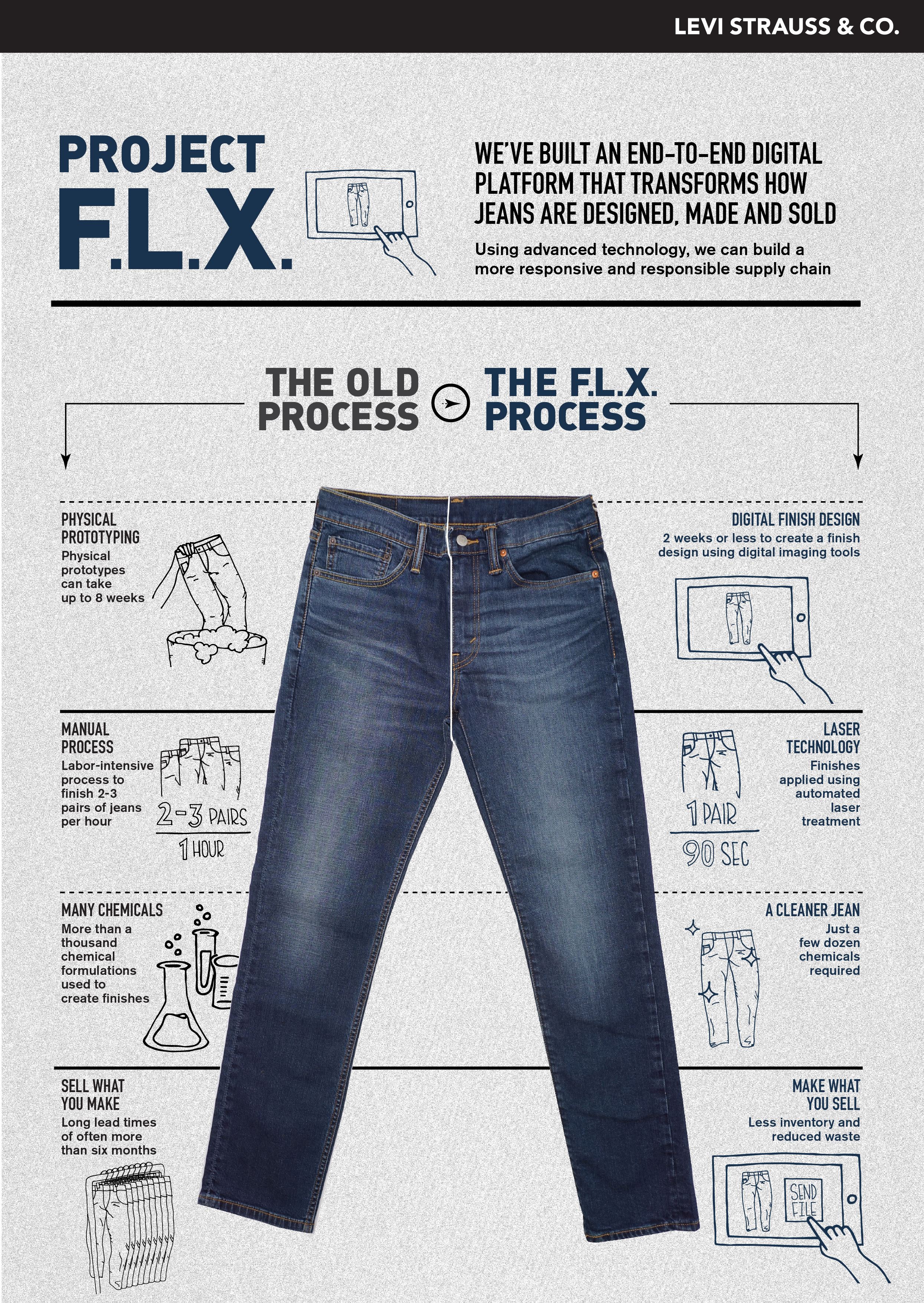

The lab’s next significant breakthrough was F.L.X., a laser finishing process that, among other benefits, helps suppliers transition away from potassium permanganate and represents a radical change from traditional methods of finishing. Today, Eureka continues to advance design, research, creative development and fashion-forward denim prototypes.

Cottonized Hemp – Less Water, Fewer Pesticides

Several Levi’s® WellThread® collections now feature “cottonized hemp”— hemp that’s been altered to feel just like cotton. Hemp requires less water and fewer pesticides to grow, but it feels coarse. The rain-fed hemp that the Levi’s® brand is using goes through a unique softening process that gives it a look and feel almost indistinguishable from cotton. This advancement marks an important step toward sustainability and circularity, and the use of cottonized hemp is one piece of our multifaceted approach toward a circular economy.

Cottonized Hemp – Less Water, Fewer Pesticides

Several Levi’s® WellThread® collections now feature “cottonized hemp”— hemp that’s been altered to feel just like cotton. Hemp requires less water and fewer pesticides to grow, but it feels coarse. The rain-fed hemp that the Levi’s® brand is using goes through a unique softening process that gives it a look and feel almost indistinguishable from cotton. This advancement marks an important step toward sustainability and circularity, and the use of cottonized hemp is one piece of our multifaceted approach toward a circular economy.

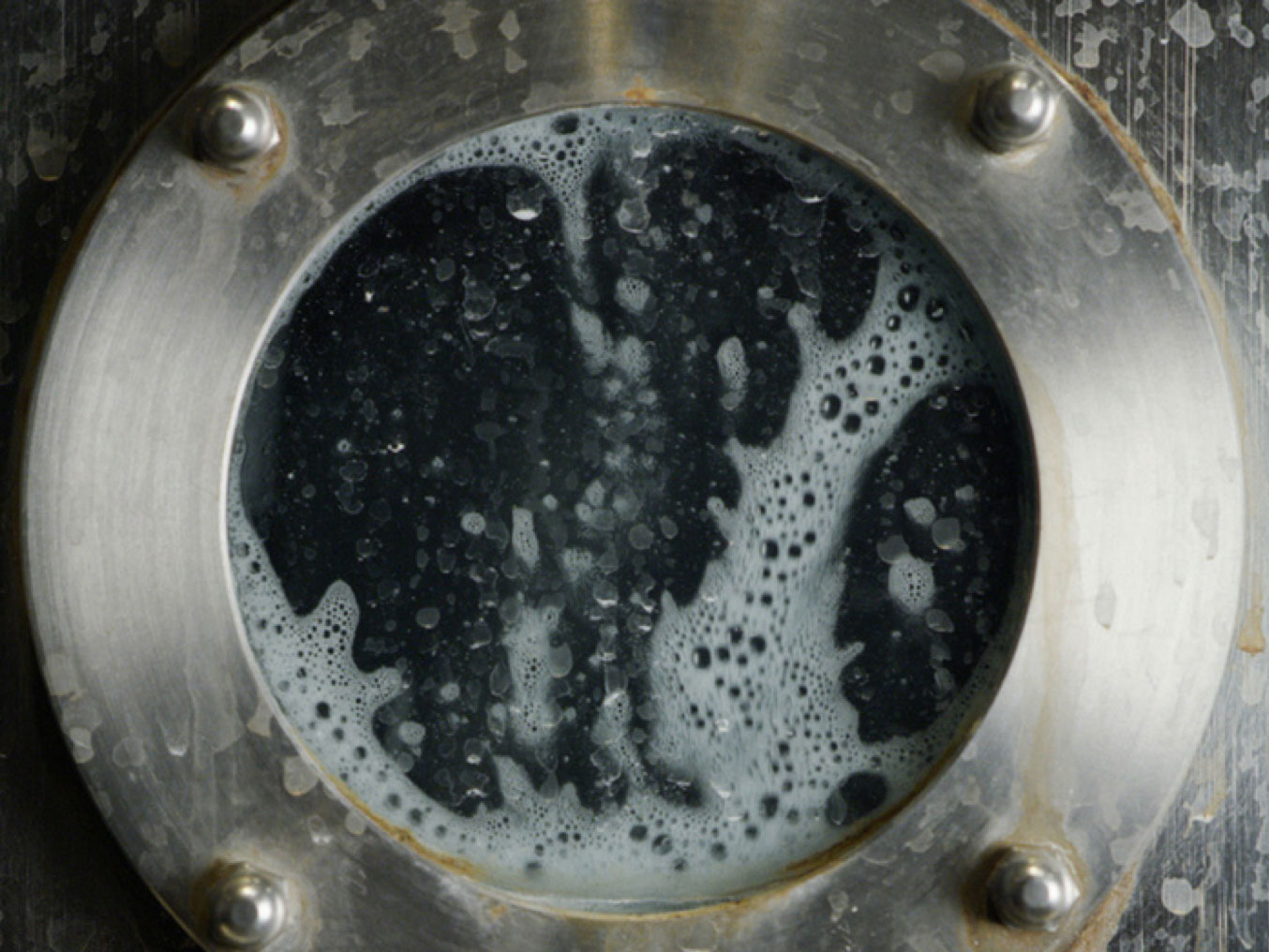

Recycling Levi’s® Products Supports Refugees

As millions of refugees and asylum seekers continue migrating in search of better lives, LS&Co. has launched various projects to help support economic stability in certain communities. The Levi’s® x Cooperative Porto Alegre is a capsule collection of handmade recycled denim products created in collaboration with the Porto Alegre Cooperative in Italy. The collection is sold in 28 Levi’s® stores and on Levi.com in 13 countries across Europe. The program not only provides refugees with training and new skills, but also donates 100% of net sales proceeds directly to the social cooperative to further support the vulnerable populations they serve.

Recycling Levi’s® Products Supports Refugees

As millions of refugees and asylum seekers continue migrating in search of better lives, LS&Co. has launched various projects to help support economic stability in certain communities. The Levi’s® x Cooperative Porto Alegre is a capsule collection of handmade recycled denim products created in collaboration with the Porto Alegre Cooperative in Italy. The collection is sold in 28 Levi’s® stores and on Levi.com in 13 countries across Europe. The program not only provides refugees with training and new skills, but also donates 100% of net sales proceeds directly to the social cooperative to further support the vulnerable populations they serve.

Digital Sampling

We are continuing to shift from the apparel industry’s traditional sell-what-you-make approach to a make-what-you-sell approach. In 2020, the Eureka Innovation Lab continued exploring how digital prototyping and renderings might be used to minimize or eliminate sample production and its associated waste. We are continuing to grow our use of digital prototyping technologies in many product categories. However, digital rendering had not been viable for denim, since it has been difficult to accurately capture the character of the fabric on a screen. But the lab is developing a working technological infrastructure through which new styles and finishes can be shared with buyers and consumers can see what products could look like.

New digital sampling capabilities help reduce the number of samples needed, which in turn preserves the resources that would have been required to make them. Coupling this approach with improved AI-based forecasting that allows us to better predict who will buy what, where and when, offers the potential to greatly reduce waste associated with overproduction. It can also reduce the amount of inventory we need to carry and minimize what’s known as “excess and obsolete” product.

F.L.X. – Future Finish®

Project F.L.X., launched in 2018 by the team at Eureka, is a 3D digital design and laser finishing technology that enables a more responsive supply chain while vastly reducing the number of chemicals needed for the finishing process. The technology has also been incorporated into our Future Finish® customization service, which offers consumers a new level of denim personalization.

Digital sampling, F.L.X. and Future Finish® together comprise a suite of digital design and manufacturing tools that are helping us work to change the prevailing apparel model from selling what we make – utilizing design forecasts determined up to 18 months in advance — to making what we sell, based on a much clearer picture of consumer tastes, with a production platform that is far more agile and much closer to the consumer. This helps us better deliver the same timeless, built-to-last products consumers want most, when they want them, saving resources and reducing waste in the process.

WellThread® - A Lab for Innovation

Our continued circularity work builds on the achievements and breakthroughs of the Levi’s® WellThread® collection, which is essentially a living R&D lab for sustainable design and innovation. First launched in 2015, WellThread® subscribes to four prevailing use principles:

- Materials and processes that prioritize environmental stewardship

- Production in facilities that support worker well-being

- Design that promotes durability and celebrates timelessness

- Garment engineering that enables efficient material recovery and reuse

Initially, the WellThread® collection was a way to push the sustainable boundaries of how we make our clothes. Today, it is a vehicle for continued progress with which we work through design and manufacturing challenges to create more innovative products that incorporate multiple sustainability attributes.

Recently that progress has come in the form of exciting innovations and styles, including new 55% hemp-blended fabrics, new natural-dye techniques, post-consumer recycled fibers, more organic cotton and the recyclability of every WellThread® garment. WellThread® innovations are helping us make sustainably produced, fully recyclable garments a reality, and as we scale them, these innovations are being brought into our mainline products. For instance, our first use of cottonized hemp was roughly 12,000 units, but we’ve scaled this innovation and delivered more than a million units in less than two years.

Even so, we don’t have all the answers. Through the WellThread® platform, we test new ideas and technologies, partnering with inventors and suppliers alike to explore the possibilities of sustainable innovation. For instance, we recognize that we need to learn more about transitional cotton — cotton on its way to becoming organic cotton in a farming and soil management process that takes about three years. We believe it is important to support organic cotton production from this transition phase onward to eventually increase access to organic cotton throughout the industry. We are looking into ways we can best support farmers as they work toward organic cotton, using the WellThread® platform, which has a history of working directly with farmers and fiber suppliers on sustainable material innovation.

The Most Sustainable Levi’s® Jean Ever

In 2020, the Levi’s® brand launched what we called our most sustainable jean ever. Made with a blend of organic cotton and Circulose® fiber — a breakthrough material from Re:NewCell made from worn-out jeans and sustainably sourced viscose — these groundbreaking jeans were named a World Changing Idea by Fast Company in 2021.

This unique collaboration between WellThread® and Re:NewCell marks a significant milestone in the fashion industry’s transition to circularity. The resulting Levi’s® WellThread® jean represents more than five years of research in circular denim design, employing a water-saving dye method and our Water<less® garment finishing practices. Parts of the jean, including all trims, labels and thread, were carefully calibrated to ensure the jeans meet recycling specifications, allowing for a second life when worn out. The fabric has 60% organic cotton and 40% Circulose® fiber, and garment components are consistent with industry norms for circular design. The result is a soft jean that lives up to our standards for quality and durability.

With any breakthrough innovation in the apparel industry, reaching commercial scale is a challenge. Startups rarely have the resources to provide large volumes of novel fibers. As Re:NewCell’s initial partner in the jeanswear sector, we produced our first jeans made with Circulose® fiber as part of the WellThread® collection. For Spring 2022 we’ve grown our use of Circulose® fiber and will introduce our first Circulose® 501® jean for the core men’s and women’s Red Tab™ assortment. LS&Co.’s early launch and sustained commitment is helping the Circulose® parent company, Re:NewCell, secure funding to expand their factory because our work together has helped them demonstrate that their technology is viable at industrial scale and can play an important role in circular fashion’s future.

*Circulose® is a registered trademark of Re:NewCell AB.

The Most Sustainable Levi’s® Jean Ever

In 2020, the Levi’s® brand launched what we called our most sustainable jean ever. Made with a blend of organic cotton and Circulose® fiber — a breakthrough material from Re:NewCell made from worn-out jeans and sustainably sourced viscose — these groundbreaking jeans were named a World Changing Idea by Fast Company in 2021.

This unique collaboration between WellThread® and Re:NewCell marks a significant milestone in the fashion industry’s transition to circularity. The resulting Levi’s® WellThread® jean represents more than five years of research in circular denim design, employing a water-saving dye method and our Water<less® garment finishing practices. Parts of the jean, including all trims, labels and thread, were carefully calibrated to ensure the jeans meet recycling specifications, allowing for a second life when worn out. The fabric has 60% organic cotton and 40% Circulose® fiber, and garment components are consistent with industry norms for circular design. The result is a soft jean that lives up to our standards for quality and durability.

With any breakthrough innovation in the apparel industry, reaching commercial scale is a challenge. Startups rarely have the resources to provide large volumes of novel fibers. As Re:NewCell’s initial partner in the jeanswear sector, we produced our first jeans made with Circulose® fiber as part of the WellThread® collection. For Spring 2022 we’ve grown our use of Circulose® fiber and will introduce our first Circulose® 501® jean for the core men’s and women’s Red Tab™ assortment. LS&Co.’s early launch and sustained commitment is helping the Circulose® parent company, Re:NewCell, secure funding to expand their factory because our work together has helped them demonstrate that their technology is viable at industrial scale and can play an important role in circular fashion’s future.

*Circulose® is a registered trademark of Re:NewCell AB.

Made from Safe and Recycled or Renewable Inputs

From supporting organic cotton farming, to sourcing recycled fibers and sustainable cellulosics, to incorporating next-generation fibers like Circulose® by Re:NewCell, we are working to consider the entire product lifecycle in our raw material sourcing.

We also have been working to remove hazardous chemicals from our supply chain for more than two decades. In 2000, we were one of the first companies to issue a Restricted Substances List. Later, we pledged to reach zero discharge of hazardous chemicals by 2020 — a goal we met — and in 2013, we launched the Screened Chemistry program. This landmark approach to safer chemicals sought to understand the potential human and environmental impact of chemicals before they enter the supply chain, and to find alternatives for anything deemed unsafe.

We are making progress toward our goal of 100% renewable electricity in all owned-and-operated facilities by 2025. As of the end of 2020, renewable electricity accounts for 76% of the total electricity at our owned-and-operated facilities. Also in 2020, a solar array went into operation at our distribution center in Henderson, Nevada, where it will meet about 20% of the facility’s electrical demand.

Because water is consumed throughout the apparel value chain, from cotton production and garment manufacture to consumer use and recycling, a circular approach demands that we make sure production, supply chain practices and technologies all support efficient water use. The LS&Co. Water Action Strategy builds on our water Recycle and Reuse Standard for suppliers, a key piece of our Water<Less® program, which in turn drives other innovations in our products and our suppliers’ processes.

Jeans Redesign Project

LS&Co. joined the Ellen MacArthur Foundation Jeans Redesign project in 2021 to help drive greater circularity in the denim world. The initiative provides guidelines for brands and suppliers to make jeans that can be used more; are designed to be made again; and are made of safe, recycled and renewable inputs — the three fundamentals of circular apparel.

The Jeans Redesign guidelines align with LS&Co.’s minimum requirements for denim jean durability, and set standards for material health, recyclability and traceability to support a circular economy. Its commitments are in step with our WellThread® collection’s established design methodology — while challenging us to deliver increased unit volume and a more transparent reporting protocol.

Jeans Redesign Project

LS&Co. joined the Ellen MacArthur Foundation Jeans Redesign project in 2021 to help drive greater circularity in the denim world. The initiative provides guidelines for brands and suppliers to make jeans that can be used more; are designed to be made again; and are made of safe, recycled and renewable inputs — the three fundamentals of circular apparel.

The Jeans Redesign guidelines align with LS&Co.’s minimum requirements for denim jean durability, and set standards for material health, recyclability and traceability to support a circular economy. Its commitments are in step with our WellThread® collection’s established design methodology — while challenging us to deliver increased unit volume and a more transparent reporting protocol.

What’s Next – Circular Economy

Building on the strong foundations provided by Water<Less® and WellThread,® we are working hard to identify and implement more sustainable practices — and reflect a circularity mindset — in our product development processes. We are committed to sourcing more sustainable materials and incorporating pioneering fibers like cottonized hemp and Circulose® into our mainline collections, such as Red Tab.™ Our suppliers are using safer chemicals and implementing processes that save water and energy. But we still need to look more holistically at the entire product lifecycle from agriculture and production, to packaging, shipping, consumer use and reuse.

At the Eureka Innovation Lab, where technical breakthroughs are born and diverse approaches, ideas and styles are championed, the team is continuing to build out our digital design and manufacturing platforms, while also contemplating ways to inspire innovation elsewhere at LS&Co. This could include inviting members of various functional departments to work at the lab to identify innovative solutions extending beyond what we think of as sustainable business today.

The Levi’s® and Dockers® brands are pursuing reliable and scalable natural dyes, including some that save water. If successful, these could help drive circularity into Tier 3 supplier operations — those that provide fibers and yarns to the mills in our supply chain — by eliminating chemical dyes from yarns. Our work with partners to continue evolving our fiber portfolio includes understanding how best to incorporate transitional cotton. In these areas and others, we don’t yet have all the solutions to the challenges of creating a truly circular apparel and less resource-intensive value chain. But we will forge ahead with our competitors and customers to find them.