On track to meet our science-based targets

During 2020, as in other recent years, unprecedented fires, heatwaves, droughts and floods demonstrated the drastic changes to our climate, highlighting the urgency for meaningful climate action and the need to support communities around the globe that continue to bear the brunt of the impact. As a company, we’re committed to doing our part to help mitigate climate change and build resilience in the face of increasingly volatile and unpredictable weather conditions. This includes reducing energy use and emissions in our own operations and our supply chain — which makes up the biggest part of our footprint — as well as supporting biodiversity and reducing waste, especially single-use plastics.

Water-Climate Nexus

Water and climate issues are inextricably connected, often called the water-climate nexus, so we approach the two in tandem. The impacts of climate change often manifest as water-related events like droughts and floods. At the same time, nearly half of all water withdrawn in the U.S. is used to keep power plants cool, and additional water is used for geothermal and other forms of renewable energy. Conversely, energy is used to pump water from aquifers for consumption, for water treatment and distribution, and for heating and cooling. This presents an opportunity for us to mitigate some water and climate impacts simultaneously. For instance, many of our Water<Less® techniques also reduce energy use by decreasing the amount of water pumped into the factory. And the International Finance Corporation (IFC) Partnership for Cleaner Textile (PaCT) program, a key pillar of our climate efforts, helps to strengthen suppliers’ water reduction performance to achieve their facility-level water targets.

An ongoing consideration in any environmental improvement initiative is the need for balance so that the reduction of impacts in one area, such as wastewater treatment, do not cause knock-on or secondary effects in others, such as energy use. The Zero Liquid Discharge program, which includes nine of our suppliers in India, is one such example. This government program incentivizes suppliers to recycle wastewater sludge onsite, but doing so requires a lot of energy. We will continue working with suppliers to balance their energy and water use on this and other initiatives for the greatest net benefit considering both local water stress and energy consumption. Through this holistic approach, we can ensure we are creating the most positive climate impact possible.

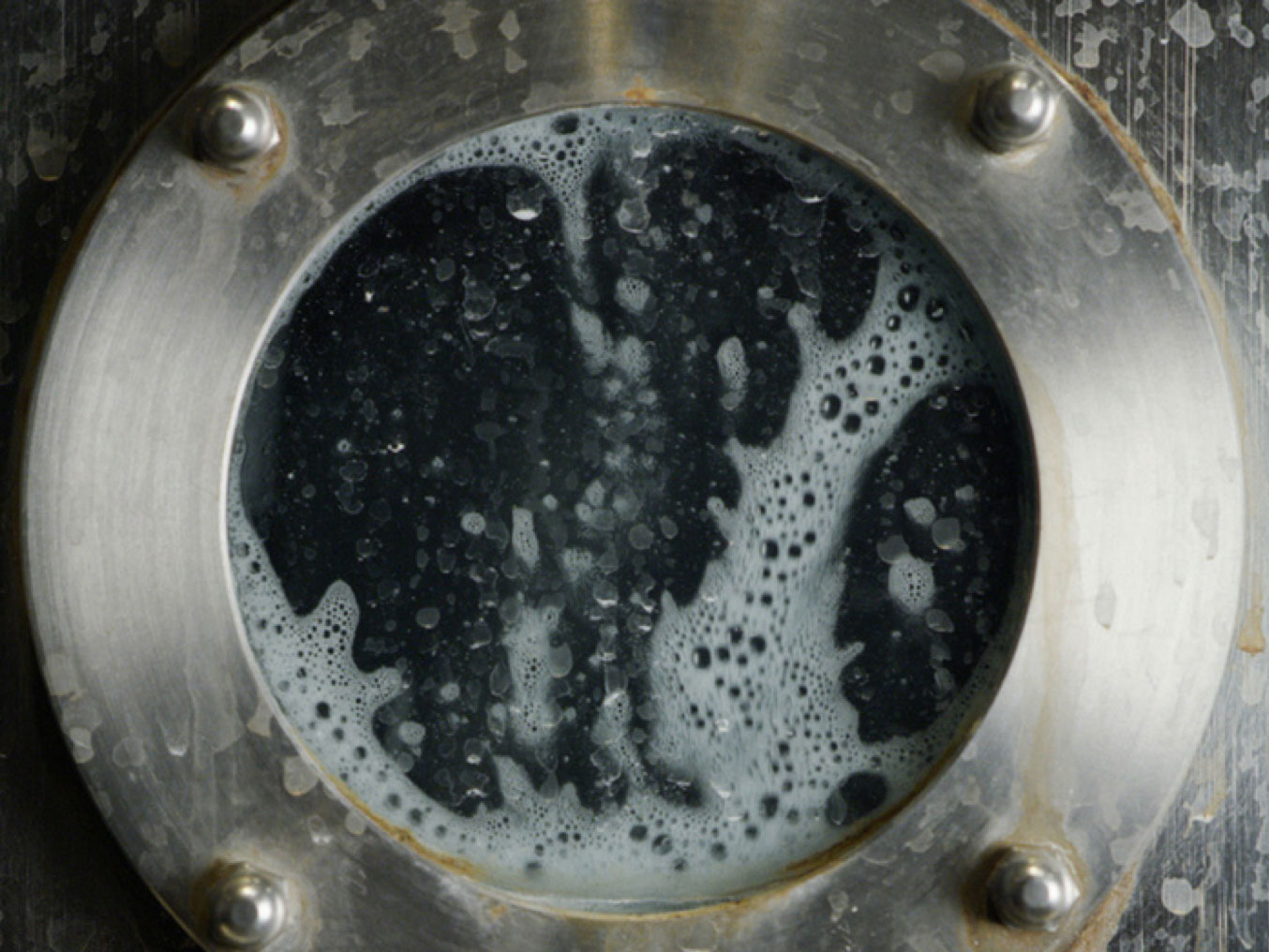

Aggressive Science-Based Targets

In 2017, we developed our Climate Action Strategy, outlining science-based emissions reduction goals across our direct operations and global supply chain. We set aggressive science-based targets to reduce emissions in our owned-and-operated facilities by 90%, shift to 100% renewable electricity* in those facilities, and reduce emissions by 40% across our supply chain — all by 2025, which is five years earlier than most of our industry. Because these targets are absolute rather than compared to company revenues, size or other economic metric, we established a baseline year, 2016, against which to measure our progress going forward. Our goals are consistent with limiting temperature rise to 1.5°C compared to pre-industrial levels. We were among the first companies in any sector to commit to emissions reductions consistent with the 1.5°C trajectory, and our targets remain among the most aggressive in our industry.

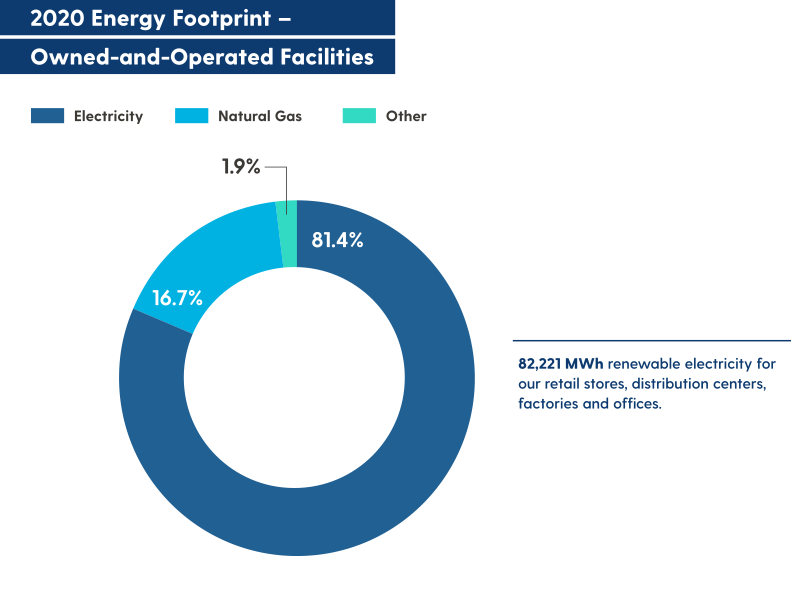

We have work to do to achieve these science-based targets, but our commitments and collaborations are driving progress. Renewable electricity accounts for 76% of the total electricity at our owned-and-operated facilities, for example, putting us ahead of schedule on our path to 100% by 2025. In 2020, we also switched on a new solar power array at our Leadership in Energy and Environmental Design (LEED) Platinum-certified distribution center in Henderson, Nevada, which will meet 20% of the facility’s electrical demand, with room to expand. Electricity makes up 81% of the total LS&Co. owned-and-operated energy footprint, so achieving our goal of 100% renewable electricity in all owned-and-operated facilities will help reduce our overall impacts.

*While it has become common to use “renewable energy” and “renewable electricity” interchangeably, they are different. Electricity refers to purchased-from-the-grid electricity, as opposed to other forms of energy, such as natural gas, diesel and other fuels.

Top Rankings for Transparent Disclosures

CDP. Formerly the Carbon Disclosure Project, CDP represents major capital markets and hundreds of investors with more than $100 trillion in assets under management. By focusing on climate change disclosures, CDP gives investors information to make decisions based on company resiliency. Since 2010, LS&Co. has disclosed our work to mitigate climate change and build greater climate resilience. In 2020, we were one of just three pure-play apparel companies that made the CDP Climate A List for transparency and management of strategies to combat climate change.

CITI. The Corporate Information Transparency Index (CITI) annual rankings, released by the Institute of Public and Environmental Affairs (IPE), rate companies leading the way on transparency and supply chain practices in China. We have consistently ranked among the top apparel companies on the list, out of hundreds of brands. In 2020, LS&Co. was ranked second among textile companies. From 2017 to 2019, we ranked in first place in the textile industry and also scored within the top three among all brands ranked across all sectors.

Top Rankings for Transparent Disclosures

CDP. Formerly the Carbon Disclosure Project, CDP represents major capital markets and hundreds of investors with more than $100 trillion in assets under management. By focusing on climate change disclosures, CDP gives investors information to make decisions based on company resiliency. Since 2010, LS&Co. has disclosed our work to mitigate climate change and build greater climate resilience. In 2020, we were one of just three pure-play apparel companies that made the CDP Climate A List for transparency and management of strategies to combat climate change.

CITI. The Corporate Information Transparency Index (CITI) annual rankings, released by the Institute of Public and Environmental Affairs (IPE), rate companies leading the way on transparency and supply chain practices in China. We have consistently ranked among the top apparel companies on the list, out of hundreds of brands. In 2020, LS&Co. was ranked second among textile companies. From 2017 to 2019, we ranked in first place in the textile industry and also scored within the top three among all brands ranked across all sectors.

Reducing Emissions in Our Own Facilities

A Stronger Baseline

In 2020, we took a more granular look at our climate target baseline to ensure integrity of the data we track. The previous footprint was based on assumptions reaching as far back as 2012. We have calculated a new baseline based on refined estimates and more recent and localized data that have improved the quality and specificity of our footprint. We had hoped to incorporate primary data from suppliers in 2020, but this continues to prove challenging. While we have successfully engaged a majority of our key suppliers on significant energy and water reduction efforts, our careful reviews have revealed the overall quality and completeness of data disclosed to the centralized systems on which we rely to be highly inconsistent. This makes it difficult to track progress and creates a need for further review and verification of data entries.

While we continue working on a solution, we have used estimates based on highly localized lifecycle analyses. Over time, we will incorporate our suppliers’ data so we can track their progress as part of our footprint — instead of separately, which is what we do now. The recalculated baseline is 4.7 million metric tons of carbon dioxide equivalent (mtCO2e), down from 5.2 million mtCO2e, which we previously disclosed.

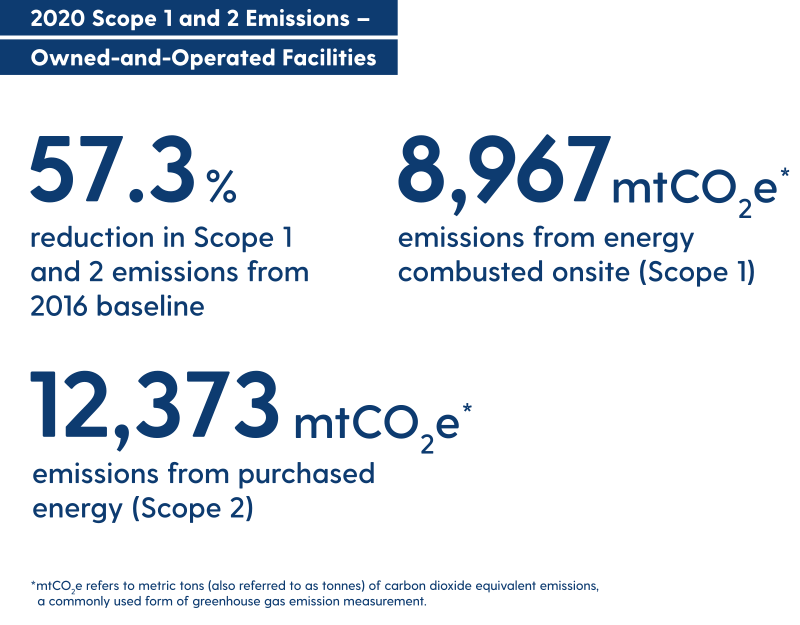

LS&Co.’s owned-and-operated facilities include more than 1,000 retail stores, more than 80 offices — including administrative and sales offices, data centers, photo studios and others — 10 distribution centers and two manufacturing plants. Emissions from our owned-and-operated activities generally fall into the Scope 1 and 2 emissions categories. Collectively, these emissions make up less than 1% of our carbon footprint. Even so, we have direct control over these emissions, so we can make meaningful change quickly. In 2020, we achieved a 57% reduction in Scope 1 and 2 emissions from the 2016 baseline, keeping us on track toward our goal of a 90% reduction by 2025. Electricity represents the majority of energy used at our owned-and-operated facilities (81% as of the end of 2020). By 2025, it will all come from renewable sources. A smaller portion of our energy (17%) is from natural gas, which we plan to reduce through efficiency improvements and purchased biogas credits.

LEED Certification

Leadership in Energy and Environmental Design, or LEED, is a widely used green building rating and certification system that provides a framework for healthy, highly efficient, and cost-saving green buildings. LS&Co. has eight LEED-certified facilities, including two recent certifications:

- LEED Platinum-certified Henderson, Nevada, distribution center, the largest of its kind to receive the Platinum designation at the time of its certification

- LEED Silver-certified Levi’s® Shanghai Beacon store, Nanjing East, a state-of-the-art 672.5 m² store that was the first Levi’s® store in mainland China to be certified LEED Silver when opened in 2020

LEED Certification

Leadership in Energy and Environmental Design, or LEED, is a widely used green building rating and certification system that provides a framework for healthy, highly efficient, and cost-saving green buildings. LS&Co. has eight LEED-certified facilities, including two recent certifications:

- LEED Platinum-certified Henderson, Nevada, distribution center, the largest of its kind to receive the Platinum designation at the time of its certification

- LEED Silver-certified Levi’s® Shanghai Beacon store, Nanjing East, a state-of-the-art 672.5 m² store that was the first Levi’s® store in mainland China to be certified LEED Silver when opened in 2020

Our Distribution Centers

Along with retail stores, the 10 distribution centers we operate make up the largest portion, about 39%, of our owned-and-operated energy footprint. We have focused heavily on energy efficiency efforts at these facilities and will continue to do so. For example, LS&Co.’s distribution center in Henderson, Nevada earned the LEED Platinum rating — the highest level of sustainable building certification — in part due to its strong energy efficiency features, such as LED lighting and motion sensors to control lights. This certification was initially achieved in 2015 and we re-certified to the more rigorous updated standard in 2020.

In 2020, as part of our climate action strategy, we built a solar installation capable of generating up to 20% of the facility’s electricity needs, while also serving as a shade structure over employee parking. This distribution center also has energy-saving features such as giant fans and LED lighting with motion sensors in the high bay area to keep the area cool and energy efficient, LED-lit vending machines, and a battery recycling station. A small factory in the basement where we use our innovative laser-based denim finishing process includes a water recycling system, furthering the resilience and environmental performance of this top-rated facility.

At Henderson, as well as our distribution centers in Rexdale, Canada, and Hebron, Kentucky, we completed American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) II audits, which provide a detailed, 360-degree view of energy usage and potential reductions. As a result, Rexdale underwent a total LEED-qualifying retrofit and converted to LED lighting.

181,780 kWh

Generated by on-site solar at Henderson facility (October – November 2020)

181,780 kWh

Generated by on-site solar at Henderson facility (October – November 2020)

Our Most Innovative Distribution Center

Development is underway for a new LS&Co. distribution center in Germany designed to feature building materials that support a circular economy and be net positive on climate and water. Groundbreaking takes place later in 2021, with operations scheduled to begin in late 2023.

The 70,000 m² solar and geothermal-powered facility will occupy a revitalized mining site in Dorsten, Germany, where it will serve as the LS&Co. European distribution center. The facility is designed to secure two certifications: Platinum-level LEED and Platinum-level WELL certification, which focuses on the health and well-being of building occupants. It also will be built according to circular design principles.

A rooftop garden will support biodiversity and serve as a water collection point to reduce heat island effects and minimize stormwater run-off. Through the use of renewable energy sources including solar and geothermal, the center is expected to meet a majority of its own energy needs. It will also reflect human-centered design, featuring communal and green areas to inspire social connection, while maximizing efficiency. As we look to future growth, the facility will serve as our standard for distribution center design.

Our Factories

Since 2013, our Plock, Poland, manufacturing facility has used 100% renewable electricity. The facility also completes regular energy audits to identify opportunities for greater efficiency and has completed a number of energy-saving projects:

- New compressor with heat exchanger to more efficiently heat production water and reduce natural gas use

- Thermo-modernization of factory steam and hot water systems to reduce energy use

- LED lighting

- New HVAC system for sewing area

- Bicycle and motorcycle parking zone to make it easier for employees to leave their cars at home

Thanks to its ongoing energy efficiency improvements, the Plock facility also generates white certificates for the country’s cap and trade system, which the government sells to properties that did not reduce energy use. White certificates are energy efficiency obligation schemes used in many European Union countries as a policy measure to reach efficiency targets.

Our factory in Epping, South Africa, has focused on lighting upgrades, has installed LED lighting throughout the facility and is planning a solar project to further reduce the need for purchased electricity. Additionally, the Epping facility has significantly reduced its water consumption through use of Water<Less® techniques — reducing water use for manufacturing by more than 25%, which indirectly improves energy efficiency because less water needs to be heated for production processes. The Epping facility has also completed a Partnership for Cleaner Textile (PaCT) assessment to identify additional potential energy efficiency improvements. Our Plock plant will complete its PaCT assessment in 2021. Both factories are also certified to the ISO 14001 Environmental Management Systems Standard, which includes guidance for managing energy use, and to ISO 45001, which covers occupational health and safety management.

Our Retail Stores

Because retail spaces need to be brightly lit, they use much more lighting per square foot than our distribution centers and factories. As a result, retail stores offer opportunities for high-impact efficiency gains through relatively small changes, such as switching to LED lighting and installing systems that dim lights after hours.

Retail Sustainability Playbook

We have also developed a Retail Sustainability Playbook based on a series of detailed energy audits and supported by regional surveys. It encourages our owned-and-operated stores to use 100% LED lighting, set energy and GHG emission performance targets, reduce energy use and costs, and develop and execute energy assessment and re-commissioning strategies. The guidance covers the store life cycle in four main areas:

- Engaging with landlords to assess the performance of HVAC equipment, the presence of LED lighting and access to renewable energy

- Creating specifications for an energy-efficient environment in keeping with our brand and customer experience expectations

- Outlining guidance for retail operations, including practices such as keeping doors closed when air conditioning is on, programming thermostats for efficiency and installing auto-shutoff lights and motion sensors

- Providing guidance for waste and water reduction

Retail Store Design

Reducing store-level energy usage is an important part of our carbon footprint reduction strategy. In addition to energy efficiency, other features under consideration for store design include sustainable materials:

- Shelves made of Straw Board, which is biodegradable, and various recycled and upcycled materials for fixtures and floors

- Printed imagery made from upcycled plastics

- Fit directory signage made with 3D printing technology from upcycled material, and décor made with non-toxic dyes and glues

- Fabric campaign graphics printed on post-consumer waste fabric

- Upcycled material fitting room walls that can be removed and reused at a new store, and wallpaper made from recyclable open-weave paper

In addition, all owned-and-operated U.S. and Canada retail locations and all U.S. wholesale locations use 100% post-consumer waste stock for print materials. Mannequins are made from 100% recycled base stock that blends both post-industrial and post-consumer materials, and we are piloting recycled denim coat hangers in several locations as well.

First Nextgen Levi’s® Store in North America

Next-generation, or nextgen, Levi’s® stores are designed to give our consumers an authentic, compelling and consistent experience with the Levi’s® brand. After piloting this store concept in Europe and Asia, in 2020 we opened the first nextgen store in North America.

Located in Palo Alto, California, the store includes a Tailor Shop where customers can customize their Levi’s® jeans, jackets and other items; digitally focused design and sustainable lighting; reimagined fitting rooms; and personalized shopping and product pick-up options. The LS&Co. Retail Sustainability Playbook provides additional guidance to reduce energy, water and waste in stores.

First Nextgen Levi’s® Store in North America

Next-generation, or nextgen, Levi’s® stores are designed to give our consumers an authentic, compelling and consistent experience with the Levi’s® brand. After piloting this store concept in Europe and Asia, in 2020 we opened the first nextgen store in North America.

Located in Palo Alto, California, the store includes a Tailor Shop where customers can customize their Levi’s® jeans, jackets and other items; digitally focused design and sustainable lighting; reimagined fitting rooms; and personalized shopping and product pick-up options. The LS&Co. Retail Sustainability Playbook provides additional guidance to reduce energy, water and waste in stores.

Product Shipping

Product shipping accounts for less than 10% of emissions in our global value chain. While ocean shipping makes up 85% of our shipments from country of origin to distribution centers, we also use other methods, including rail, trucking, barge transport and air freight, depending on location and the distance a shipment has to cover, weighed against the emissions profile of available options. For instance, within Europe, shipping by rail instead of air significantly lowers our emissions because air freight is 24 times more carbon intensive (per metric/kilometer) than rail. In Asia, we use barge transport along rivers where possible, which offers lower emissions than trucking. And in the U.S., truck transportation is being replaced by rail from port to inland distribution centers, with the intention to increase intermodal rail connections in the coming years.

Maersk, our largest global shipping partner, has an ECO Delivery program that uses waste-based biofuels to move large containers with net zero CO2 emissions. In 2020, we shipped 500 containers through ECO Delivery, a number that will increase to 1,000 containers in 2021. Likewise, LS&Co. has been a member of the Clean Cargo Working Group since 2018. This allows us to work with like-minded shippers, forwarders and carriers to integrate sustainability into the freight procurement process, and to access global carriers’ emissions data for more informed transportation decision making.

We are also collaborating with Maersk, other companies and a university as part of the LEO Coalition, which is exploring the environmental benefits and commercial viability of LEO — a blend of lignin and ethanol — that could support sustainable shipping. A structural bio-polymer found in plants, lignin is also a byproduct of the paper industry. It is often disposed of through incineration to produce steam and electricity.

Optimizing Shipping Cartons

Our products move around the world in large shipping containers that travel by sea, rail, air and land. A recent initiative to redesign the outer carton housing our products allows each one to be packed more densely, which allows us to fit more cartons into a container and ship fewer cartons overall. We evaluated the packing process and existing carton configuration, then determined that 90% of products could be optimized by packing them in just two footprints. Refining the carton design by just 1.5 inches on one side and 2 inches on the other side saves 17% of container space. So far, the new carton design has been introduced in seven countries, leading to a reduction in carbon emissions in 2020. We intend to roll out the new cartons in the Americas to achieve further size, space and emissions reductions.

Our owned-and-operated distribution centers reuse a majority of the cartons that come into the facility from suppliers, repack them and ship products out to large retail customers. Of the remaining cartons, about 7% arrive damaged and get broken down for recycling, as do any cartons not needed for reuse.

Direct Ship

A shipping system that streamlines the shipping and distribution process, allowing certain shipments to go directly to the retail customer without stopping at a distribution center. It involves a close partnership with our third-party logistics provider to make sure they have the necessary labeling in place for certain retail accounts. To date, we have initiated Direct Ship with several smaller-scale third-party retailers and are looking to scale it to much larger retailers such as Target, Walmart and Costco to reduce packaging waste and transportation emissions even further.

Direct Ship

A shipping system that streamlines the shipping and distribution process, allowing certain shipments to go directly to the retail customer without stopping at a distribution center. It involves a close partnership with our third-party logistics provider to make sure they have the necessary labeling in place for certain retail accounts. To date, we have initiated Direct Ship with several smaller-scale third-party retailers and are looking to scale it to much larger retailers such as Target, Walmart and Costco to reduce packaging waste and transportation emissions even further.

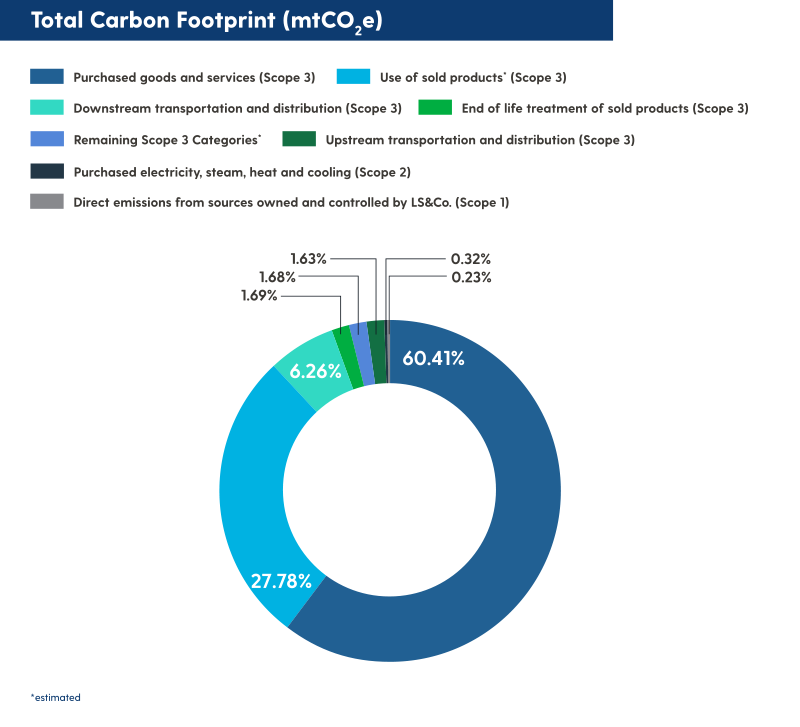

Reducing Emissions in Supplier Facilities

LS&Co. estimates one of the most comprehensive climate footprints in the apparel industry, including all Scope 3 Greenhouse Gas Protocol categories identified as relevant to LS&Co. operations (11 of 15). Of these, the biggest contributor to our footprint is our supply chain, referred to as Purchased Goods and Services (Category 1), and representing 60.4% of our footprint in 2020. To make progress on these impacts and achieve our climate goals, we must collaborate with our suppliers. That means working with them to set clear and ambitious targets, while also supporting their efforts to become more water and energy efficient and increasing their use of renewable electricity.

Between 2017 and 2020, we reduced Scope 3 emissions — those associated with our supply chain — by 14% over our 2016 baseline. This progress is on track to meet our 2025 science-based target of a 40% reduction. However, several conditions associated with such an unprecedented year contributed to the reduction. For instance, sourcing mix changes and sourcing base location changes played a role in reducing supply chain emissions, as did improvements to the electrical grid in some locations. Our continued efforts to source more sustainable raw materials, such as more sustainable cotton and responsible manmade cellulosics, also played a role in reducing emissions.

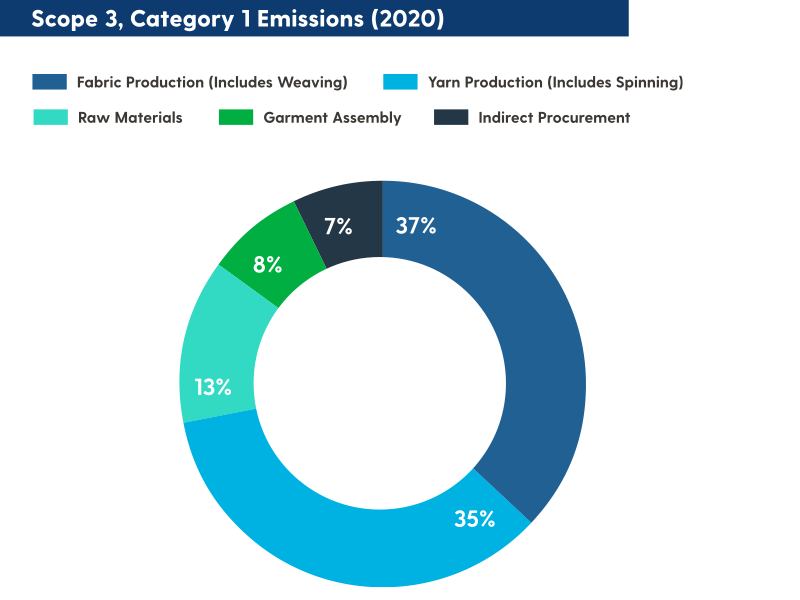

How We Help Suppliers Set Targets

Fabric mills and garment manufacturers account for the majority of our full value chain carbon footprint, especially given that many of our fabric mills are also yarn spinners. We are working with our key suppliers — those representing approximately 80% of final product volume — in these two supply chain tiers to make sure their emission reduction targets are at least 40%. To date, key suppliers have agreed to targets between 40% and 60%. Achieving these goals will require not only facility changes to equipment, but also investment in renewable energy of multiple forms.

How We Help Suppliers Set Targets

Fabric mills and garment manufacturers account for the majority of our full value chain carbon footprint, especially given that many of our fabric mills are also yarn spinners. We are working with our key suppliers — those representing approximately 80% of final product volume — in these two supply chain tiers to make sure their emission reduction targets are at least 40%. To date, key suppliers have agreed to targets between 40% and 60%. Achieving these goals will require not only facility changes to equipment, but also investment in renewable energy of multiple forms.

Supplier Support through the Partnership for Cleaner Textiles

Since 2017, we have collaborated with the International Finance Corporation (IFC), the financing arm of the World Bank, on the Partnership for Cleaner Textile (PaCT). This innovative public-private partnership provides access to advisory services to suppliers who wish to invest in reducing their energy, greenhouse gas and water footprints, but need technical support or upfront capital to do so.

We initially engaged six key suppliers’ manufacturing sites in South Asia, focusing on a PaCT assessment and solar pre-feasibility study in factories and mills (Tier 1 and Tier 2 suppliers). After these 2017 pilot programs showed real savings and efficiency improvements, we expanded availability to about 30 factories and mills in seven countries as of mid-2021. Within the next several years, we plan to engage the remainder of our key factories and mills globally. As part of this program, LS&Co. is covering the costs for eligible suppliers to undergo a renewable electricity assessment. Where onsite renewable investment is feasible, we will collaborate with the IFC on a financing model, leveraging the IFC Global Trade Supplier Finance (GTSF) program, in which we have been involved since 2014. The GTSF program is making available approximately $120 million for participating suppliers developing products for LS&Co.

Even more recently, in 2021, we expanded our partnership with IFC to provide further support to suppliers that have already begun implementing low-carbon investment plans and have conducted PaCT energy assessments. This includes offering them access to lower-cost financing to support their efforts, and together, deliver meaningful climate action.

This program enables suppliers to access competitively-priced financing based on criteria such as strong performance on our Terms of Engagement — LS&Co.’s supplier code of conduct. It provides access to capital for sustainability investments, which the supplier may otherwise not be able to finance. As of early 2021, participating suppliers have reduced their GHG emissions and energy use by an average of 5.3% and 6.9%, respectively, per metric ton of product. Suppliers have also reduced water use by 1.75% per metric ton of product. These initiatives have helped participating suppliers save $2.4 million in operating costs in total.

Where IFC has not launched the PaCT program, we encourage supplier participation in Clean by Design, a program now overseen by the Apparel Impact Institute and served by RESET Carbon. LS&Co. previously participated in this program when it was operated by the Natural Resources Defense Council. In China, 10 fabric mills that are part of our supply chain participated in Clean by Design between 2016 and 2020. The Clean by Design approach to supply chain efficiency works to improve supplier use of both energy and water.

Supplier Climate Roadmaps

Until recently, it has been hard to accurately measure emissions in our supply chain. Our brands are rarely the majority customer at the factories and mills we source from. This means we have to work closely with suppliers to understand what percentage of emissions correspond to our operations, and to help them recognize the benefits of reducing their energy and emissions and embrace opportunities to improve performance in these key categories.

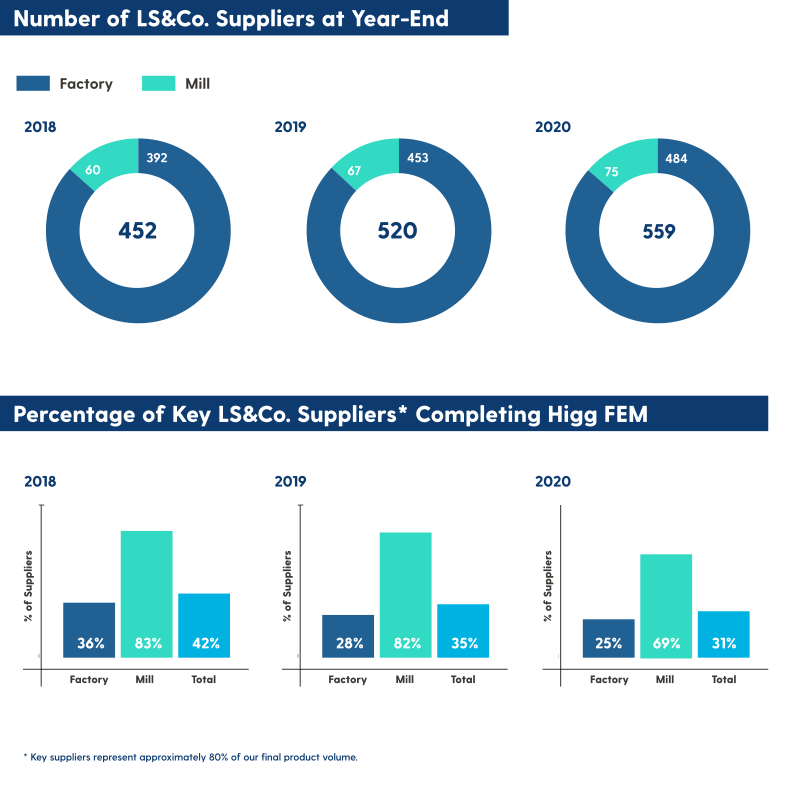

In 2020, we collaborated with our key suppliers to make sure they could collect the necessary data and get it verified through the Sustainable Apparel Coalition’s Higg Facility Environmental Module (FEM). We had the data further reviewed by IFC, then applied it to create supplier roadmaps for change.

The resulting supplier roadmaps include:

- Baseline energy and water usage

- Current year energy and water usage

- Progress to date against their supplier targets for carbon emissions, renewable electricity, and water reduction

- A living 2025 action plan developed by the supplier

These roadmaps will guide suppliers as they make both big changes — such as replacing an old coal-fired boiler — and smaller ones, such as adding more efficient lighting. Along the way, we will provide resources and other support, such as innovative financing mechanisms and educational webinars, to help them implement changes. Their success at meeting their climate targets, and ours, depends on it.

Supporting Renewable Electricity through Power Purchase Agreements

A solar power purchase agreement (PPA) is a financial agreement where a developer arranges for design, permitting, financing and installation of a solar energy system on a customer’s property at little to no cost. In 2021, we began exploring a group PPA in Pakistan in partnership with the International Finance Corporation (IFC). The PPA would reach multiple factories where opportunity exists to source onsite or offsite local solar energy at a better rate than the existing energy market. This work and projects like it will have a positive impact on our Scope 3 footprint.

Supporting Renewable Electricity through Power Purchase Agreements

A solar power purchase agreement (PPA) is a financial agreement where a developer arranges for design, permitting, financing and installation of a solar energy system on a customer’s property at little to no cost. In 2021, we began exploring a group PPA in Pakistan in partnership with the International Finance Corporation (IFC). The PPA would reach multiple factories where opportunity exists to source onsite or offsite local solar energy at a better rate than the existing energy market. This work and projects like it will have a positive impact on our Scope 3 footprint.

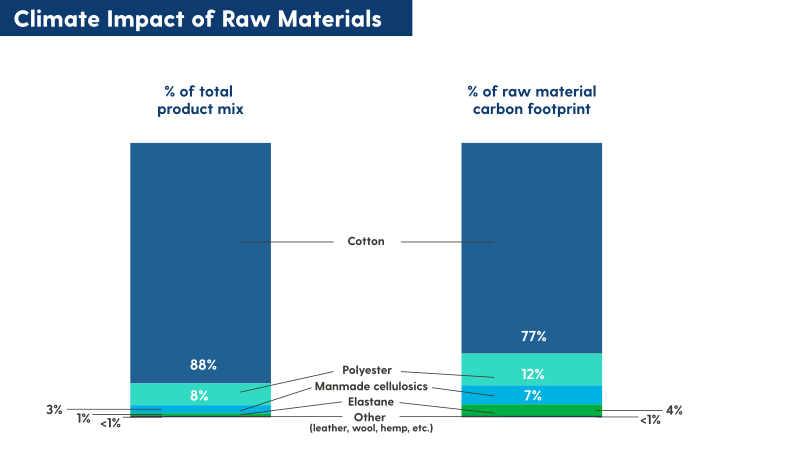

Reducing Fiber Impacts

We recognize the climate impact of our raw materials and are continually assessing and developing programs to reduce impacts related to their cultivation and processing. As of mid-2021, we are working on two key actions:

- Understanding which materials are most carbon intensive and identifying interventions to minimize energy use, and

- Understanding our use of petroleum-based inputs in order to reduce our reliance on fossil fuel-derived materials.

Of the raw materials in our portfolio, manmade cellulosic fibers are one of the most energy intensive, with the most energy consumed processing the raw material into fibers and spinning the fibers into yarn. Identifying this area of impact enabled us to assess the manufacturing and energy management practices of manmade cellulosic suppliers in order to set guidance for our sourcing practices. We now work with a select set of manmade cellulosic suppliers that use renewable energy and energy reduction programs.

We also use a small amount of polyester, nylon and elastane — materials that are not only made from fossil fuels, but are also energy intensive to process into yarn. In light of these issues, we have initiatives in place to reduce our use of these virgin synthetic fibers. We are using recycled polyester and nylon in outerwear and accessories, and using recycled elastane in some of our collections. Going forward, we will continue to minimize our use of virgin synthetic materials, opting for more sustainable alternatives, with the intent to reduce our climate impact.

We are also developing and implementing initiatives to reduce the petroleum-based inputs in our raw materials. Noting that cotton, our most significant raw material, is a natural fiber typically grown with synthetic pesticides and fertilizers, we have undertaken efforts to reduce these petroleum-based inputs. Specifically, we have worked with the Better Cotton Initiative since 2010 to invest in reducing fossil fuel-based chemicals in global cotton agriculture. Similarly, our partnership with the U.S. Cotton Trust Protocol promotes farming practices to reduce synthetic chemicals for better soil health, which in turn can absorb more carbon dioxide. Finally, our support of organic cotton farming provides the greatest climate impact reduction related to our raw materials, as those farmers have eliminated petroleum-based chemical use and are maintaining soil health to the certified organic standard.

2020 Climate Data Limitations

Our supplier-level climate, or energy, data for a given year, as well as supplier water use data, comes from third-party-verified Higg data we receive in September of the following year. Our approach to addressing this challenge with water data is described in Water Stewardship. For climate, we have used estimates based on highly localized and manufacturing step-specific product lifecycle analyses. Over time, we will incorporate primary supplier data so we can track their progress as part of our footprint.

For 2020, we decided to make the third-party data verification step optional to help suppliers address costs in light of the pandemic’s financial impacts on their businesses. As of this report’s publication, many suppliers had not yet submitted their Higg data. This affects results for both our climate and water footprints.

Collaborating for Change

Collaboration and partnerships are crucial to driving impact outside our four walls. We join forces with other brands, with our suppliers and with other external partners in pursuit of coordinated, systems-level change.

International Finance Corporation

In 2020 we set renewable energy and emissions targets with 59 key garment manufacturers and fabric mills — with more to come.* At the same time, we initiated work to support these suppliers in developing facility-level roadmaps for energy efficiency and emissions reduction. A four-year partnership among the LS&Co. finance team, sustainability team and International Finance Corporation (IFC) is enabling this work by providing suppliers with resources and financing to invest in both energy and water efficiency. In addition to the PaCT work with IFC, we have several other key partners in our efforts to drive meaningful climate action in and beyond our business.

*We define “key” suppliers or vendors as those manufacturing facilities responsible for approximately 80% of LS&Co.’s final product volume.

Business for Innovation Climate and Energy Policy

As one of the founding members of the Business for Innovative Climate and Energy Policy (BICEP) network, we advocate for science-based climate and energy policy to accelerate the transition to a more resilient clean energy economy. In 2020, for example, we engaged in successful advocacy for the adoption of California’s Advanced Clean Truck Rule and commitments by 14 other states and Washington D.C. to transition to 100% zero-emission medium- and heavy-duty vehicles. We are also a signatory to the Fashion Industry Charter for Climate Action, which is committed to reducing the apparel industry’s greenhouse gas emissions to zero by mid-century.

Making the Business Case for Climate Policy

In 2020, we joined the BICEP network and more than 300 companies in a virtual Lawmaker Education and Advocacy Day on Climate. We also collaborated with more than 30 leading companies on a letter to the U.S. Congress, calling for a climate-smart economy recovery from the COVID-19 pandemic and an extension of clean energy tax credits. The U.S. Congress passed legislation extending those credits and addressed another LS&Co. advocacy priority by agreeing to phase down production and use of hydrofluorocarbons — refrigerants with global warming potential 1,000 to 3,000 times that of carbon dioxide.

At the state level in the U.S., we have successfully advocated for numerous climate-related measures, including the adoption of California’s Advanced Clean Truck Rule, which introduces requirements to increase electric truck sales to 30% of total truck sales by 2030 and to 100% by 2045.

Continued Support for the Paris Climate Agreement

Since 2015, LS&Co. and CEO Chip Bergh have been vocal advocates for a strong Paris Agreement. We believe this is a must to drive coordinated global action to address the climate crisis. In 2020, upon the U.S. withdrawal from the Paris Agreement, LS&Co. joined a We Are Still In letter with cities, companies, and financial, educational, healthcare and faith organizations endorsing the goals of the Paris Agreement and committing to collaborate with the Biden-Harris Administration on science-based climate action. Then, following the U.S. re-entry into the agreement, LS&Co. participated in a successful campaign calling on President Biden to institute a national 2030 GHG emissions reduction target of at least 50%.

Our CEO also signed a business letter calling on the European Union to increase the ambition of its commitment to the Paris Agreement and 2030 GHG emissions reduction target. The European Commission ultimately adopted the science-based target called for in the letter.

Fashion Industry Charter for Climate Action

As a signatory to the Fashion Industry Charter for Climate Action, we are committed to support the implementation of its principles, both by pursuing the principles within our own organization and by working collectively with other signatories. The Charter is an initiative of the United Nations Framework Convention on Climate Change.

In 2020, LS&Co. signed a letter of UN Fashion Charter members to the office of the Prime Minister of Vietnam, encouraging adoption of a proposed direct power purchase agreement pilot program, which would increase renewable electricity options for businesses in Vietnam. And we have joined the call for the establishment of a national Clean Electricity Standard in the U.S.

What’s Next – Climate Action

We are making progress reducing our own greenhouse gas emissions, achieving a 57% reduction in Scope 1 and 2 emissions in 2020 from the 2016 baseline. We also procure 76% of our electricity from renewable sources for use in our owned-and-operated retail, distribution and manufacturing operations. But to meet the reduction trajectories needed to limit global temperature rise to 1.5°C and avoid the worst of climate change, we must continue focusing on energy efficiency and emission reductions in our supply chain.

We will continue our partnership with IFC to engage even more suppliers in the PaCT program. And we will work closely with suppliers participating in Clean by Design to make sure they have access to the resources they need to meet their energy and emissions reduction targets.

Fabric mills and garment manufacturers together account for nearly half of our carbon footprint. We are working with the key suppliers — those representing approximately 80% of final product volume — in these two supply chain tiers to make sure they are setting aggressive facility-level carbon-equivalent emissions reduction targets and renewable energy procurement targets. To date, key suppliers have agreed to reduction targets between 40% and 60%.

Achieving these goals will include not only facility changes to equipment, but also involve incorporating more sustainable raw materials into the fabrics used in our products. We plan to work with additional suppliers on target setting as well. In 2022, we will continue collaborating with our key suppliers to make sure they are positioned to access the resources needed to implement their climate roadmaps. Strengthening supplier performance measurement and supporting their engagement on effective reduction pathways and renewable energy projects also will be key because our target cannot be met by efficiency upgrades alone. We will also engage the rest of our suppliers, including licensees, as well as footwear, accessory, and sundry suppliers.

We plan to fully roll out the next-generation Retail Sustainability Playbook, incorporating its guidance on energy, water and waste reduction as well as behavioral changes for reduced energy use in retail stores. We are also building questions into our retail real estate review process regarding HVAC age, availability of renewable energy and lighting efficiency. To take the new building plans and specifications to the next level of efficiency, we are working to standardize heating and air conditioning units. Our analysis uses life cycle management tools to link the energy and cost savings of various options with the intent of identifying the best options going forward, considering country, market, region and climate. Not only will standardized heating and cooling systems help reduce energy and emissions, but will also eliminate construction change orders and inefficiency.