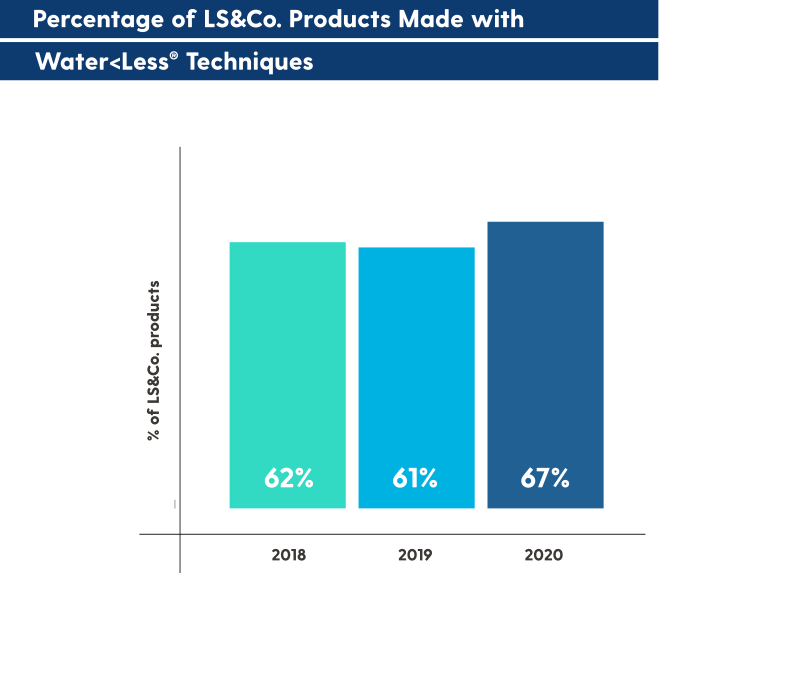

At our owned-and-operated factories in Poland and South Africa, a variety of water-savings processes are in place. Both facilities use Water<Less® production processes and have installed water efficient retrofits on washing machines.

In addition, our facility in South Africa recently created an innovative public-private partnership with the Cape Town municipal government to construct a pipeline to return recycled water from the municipal treatment plant to Epping. The team also installed a water treatment plant that receives and treats the recycled water, enabling the facility to use 100% recycled water in manufacturing, rather than relying on the stressed local freshwater supply.

At the same time, product development and finishing teams increased their use of LS&Co.’s Water<Less® finishing techniques, which reduced water use for manufacturing by more than 25%. These actions allowed our factory to decouple its production from Cape Town’s fresh water, helping to protect local water supplies and build resilience to future water shortages.

In addition, LS&Co. grants to The Nature Conservancy’s Greater Cape Town Water Fund enabled training and work for local women who have been removing invasive shrubs, freeing up more than 120 million liters for the local water supply — part of the 4.8 billion liters of water freed up per year under the fund.